Precision Perfected: Materials Test Lab Insights for Success

Wiki Article

Putting Products to the Test: Exploring the Duty of Products Examination Labs

Materials examination laboratories play a crucial function in making sure the quality and reliability of different products made use of in markets such as building, aerospace, and production. These laboratories carry out rigorous screening to examine the efficiency, strength, longevity, and security of products, allowing firms to make enlightened choices concerning their usage in frameworks and products. Through a combination of sophisticated strategies and customized devices, products examination labs are able to examine the homes of metals, polymers, composites, and other products under numerous problems and stressors. The results acquired from these tests supply beneficial understandings into product behavior, enabling engineers and designers to enhance their products and procedures. This post will certainly explore the relevance of materials screening, the sorts of products evaluated, testing strategies and tools made use of, in addition to the applications of products test results. In addition, it will certainly review future patterns in materials testing, highlighting the continual innovations in this area.Importance of Materials Screening

Regularly assessing the high quality of products is critical in ensuring the integrity and safety and security of items in numerous markets. Products screening entails subjecting products to various tests and experiments to examine their mechanical, physical, and chemical residential properties.One of the key reasons why products screening is vital is the guarantee of product top quality. Through extensive screening, suppliers can recognize any kind of defects or weaknesses in the materials utilized for their items.

In addition, products screening is important for making sure the security of items - materials test lab. By subjecting products to different examinations, suppliers can establish their strength, resistance, and resilience to exterior variables such as warmth, pressure, or chemicals. This info is important in developing and manufacturing products that are secure for customers to utilize. Whether it is automobile parts, medical gadgets, or building products, products screening helps in recognizing any kind of prospective security hazards and creating proper procedures to reduce them.

Sorts Of Products Tested

Different kinds of materials are checked in products test labs to review their mechanical, physical, and chemical homes. These materials can include a large range important, consisting of steels, polymers, ceramics, compounds, and also all-natural materials such as wood and concrete.Steels are commonly evaluated because of their prevalent use in different markets. These examinations assess residential properties such as tensile toughness, firmness, and ductility. Polymers, on the various other hand, are checked to determine their elasticity, thermal security, and resistance to chemicals. Ceramics are examined for their brittleness, stamina, and resistance to high temperatures. Composites, which include two or more various products, are reviewed to recognize their total efficiency, consisting of factors like strength, resilience, and adaptability.

All-natural materials like timber are examined to examine their stamina, dampness material, and resistance to degeneration (materials test lab). Concrete is one more commonly examined material, with tests concentrating on its compressive stamina, resilience, and resistance to ecological elements

Along with these materials, products test labs additionally assess coverings, paints, adhesives, and numerous other materials utilized in construction, production, and various other industries. By subjecting these products to rigorous testing, scientists and designers can gather important information to educate material option, design optimization, and high quality control procedures.

Testing Strategies and Tools

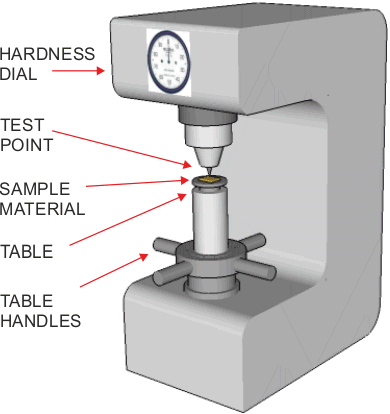

Evaluating methods and tools play an important duty in products test laboratories for assessing the mechanical, physical, and chemical buildings of various materials. These strategies and tools are necessary in guaranteeing the top quality, integrity, and safety of materials utilized in different markets such as aerospace, auto, construction, and medical.One typically utilized screening method in products examination laboratories is mechanical screening, which involves subjecting materials to various forces or loads to determine their strength, hardness, ductility, and other mechanical homes. This is usually done using equipment such as global screening equipments, which can use tensile, compressive, and flexing forces to evaluate samplings.

Physical screening strategies are additionally used to analyze properties such as thickness, thickness, thermal conductivity, read more and electrical conductivity. Equipment such as thickness meters, viscometers, thermal conductivity analyzers, and electrical conductivity meters are made use of to perform these examinations properly.

Chemical testing techniques are used to figure out the chemical structure and purity of products. Strategies such as spectroscopy, mass, and chromatography spectrometry are commonly made use of, together with specialized tools made for these functions.

Applications of Products Examination Outcomes

The results of materials testing provide useful understandings right into the performance and suitability of different materials for details applications in different markets - materials test lab. These test results play a vital duty in identifying the quality, resilience, and safety and security of materials utilized in manufacturing proceduresAmong the crucial applications of products examination results is in the field of building and construction. Designers and designers depend on these outcomes to pick ideal products for constructing structures, such as bridges, high-rises, and property buildings. By carrying out tests on materials like concrete, wood, and steel, they can ensure that these materials meet the required requirements and can withstand different environmental problems.

In the aerospace sector, products test results are crucial in determining the suitability of products for airplane components. By subjecting products to strenuous testing, designers can assess their mechanical residential or commercial properties, resistance to heat and rust, and capability to withstand high-stress problems. This info is important in ensuring the safety and dependability of aircraft.

Future Patterns in Products Testing

In the realm of materials testing, advancements in materials evaluating approaches are shaping the trajectory of the area, ushering in a brand-new age of advancement and accuracy. As modern technology proceeds to progress, so does the requirement for advanced testing strategies and devices. One future trend in products testing is the assimilation of man-made intelligence (AI) and artificial intelligence algorithms right into testing processes. These innovations have the prospective to improve the performance and accuracy of examination outcomes by examining large quantities of information and recognizing patterns that might not be conveniently obvious by human beings. Additionally, making use of non-destructive screening techniques is becoming increasingly prominent. These approaches allow for the analysis of product homes without triggering damage or modification to the example, making them ideal for checking useful or irreplaceable materials. Additionally, there is an expanding emphasis on sustainability in products screening. This consists of the advancement of testing approaches that lessen waste and energy usage, as well as using environmentally-friendly products in testing equipment. On the whole, the future of products testing is identified by continuous development and a commitment to improving effectiveness, sustainability, and precision.Verdict

Finally, products testing plays an essential role in numerous sectors by guaranteeing the high quality, security, and performance of materials utilized in frameworks and items. It includes testing a broad variety of materials using numerous strategies and devices to assess their mechanical, physical, and chemical residential properties. The results gotten from materials screening are utilized to make educated choices in material manufacturing, style, and choice processes. As technology advancements, products evaluating laboratories will certainly remain to adjust website here and boost their methods to fulfill the evolving needs of industries.Through a mix of innovative methods and specialized devices, products test laboratories are able to evaluate the homes of metals, polymers, composites, and various other materials under different conditions and stress factors. By performing tests on materials like steel, concrete, and timber, they can ensure that these products meet the required standards and can stand up to numerous ecological problems.

In the aerospace market, products examination results are necessary in figuring out the viability of products for airplane elements. By evaluating products for their toughness, resistance, and versatility to impact, makers can choose the most ideal products for different auto components, such as body panels, engine components, and safety and security attributes.In the realm of materials screening, innovations in products examining methodologies are shaping the trajectory of the field, ushering in a brand-new period of advancement and precision.

Report this wiki page